Products

Here is an introduction to our products. HM HYDRO will meet the various demands of our customers by taking advantage of our advanced technology and know-how accumulated over the years.

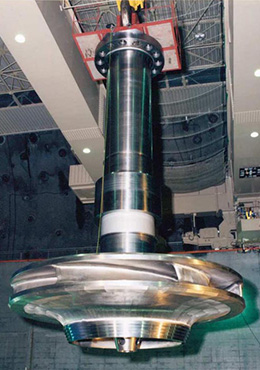

Turbines and Pump Turbines

Our water turbines and pump turbines can meet a wide range of customer needs because HM HYDRO designs turbines optimized for various head and discharge. Our product lineup includes Francis turbines, Kaplan turbines, Pelton turbines, Deriaz turbines, Bulb turbines, etc. The characteristics and performance of our turbines are verified through our own model tests stand to ensure excellent efficiency and stability.

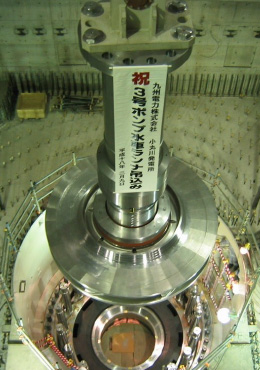

Hokkaido Electric Power Co., Inc.

Hokkaido Electric Power Co., Inc.

Takami Power Station

103MW Deriaz type pump turbine (adjustable-speed)

Kansai Electric Power Co., Inc.

Kansai Electric Power Co., Inc.

Okutataragi Power Station

310MW Francis type pump turbine (adjustable-speed)

Laos

Laos

Nam Ngiep 1 Main Power Station

141MW Francis type water turbine

Kyushu Electric Power Co., Inc.

Kyushu Electric Power Co., Inc.

Omarugawa Power Station

310MW Francis type pump turbine

(adjustable-speed)

Tokyo Electric Power Company Renewable Power Company

Tokyo Electric Power Company Renewable Power Company

Kazunogawa Power Station

412MW Francis type pump turbine

Inlet valves

HM HYDRO designs and manufactures highly reliable inlet valves for hydroelectric power plants that have been proven over many years of experience. HM HYDRO supplies high-quality inlet valves tailored to the specifications of each power plant, including biplane valves, which are the most commonly used for the inlet valves for hydraulic power plants, and spherical valves, which are mainly used for inlet valves for high head turbines, to meet the various needs of our customers.

Purulia Power Station, India

Purulia Power Station, India

Inlet valve (spherical valve) for 260MW pumped storage power plant

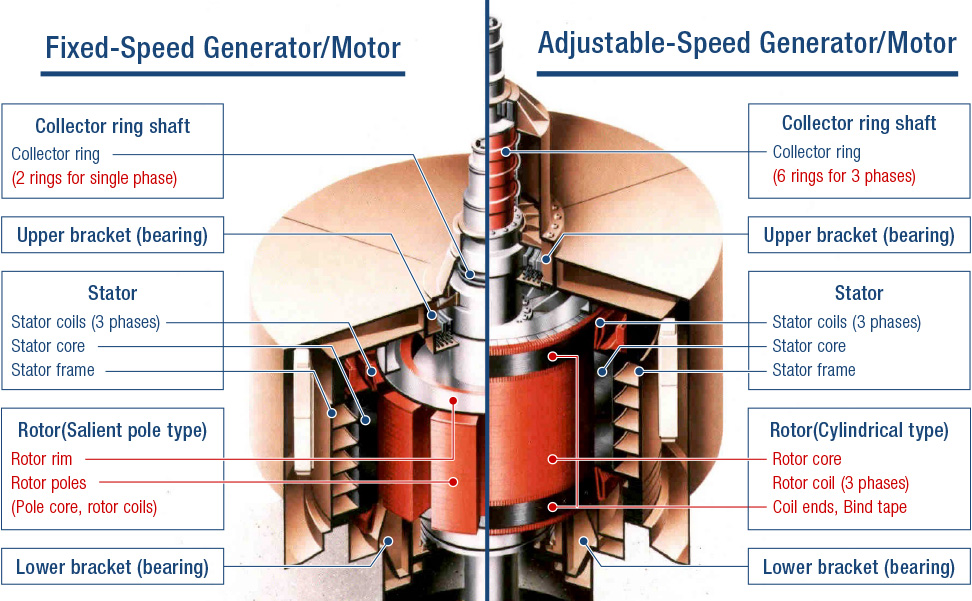

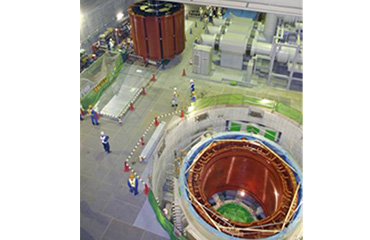

Generators and Generator-Motors

HM HYDRO designs and delivers hydroelectric generators worldwide to meet the unique power generation capacities and rotational speeds of each plant. For the generator-motors used in pumped storage power plants, HM HYDRO offers both constant-speed machines that operate at a constant rotational speed and adjustable-speed machines with variable rotational speeds, and HM HYDRO can also replace constant-speed machines with adjustable-speed machines. With these technologies and products, HM HYDRO contributes to the stability of power supply and power systems.

Structure of Generator/Motor(Fixed-speed machine and adjustable-speed machine)

Structure of Generator/Motor(Fixed-speed machine and adjustable-speed machine)

Kansai Electric Power Co., Inc.

Kansai Electric Power Co., Inc.

Okutataragi Power Station

350MVA Generator-motor Rotor

(fixed-speed machine)

*Before renovation

Kansai Electric Power Co., Inc.

Kansai Electric Power Co., Inc.

Okutataragi Power Station

350MVA Generator-motor Rotor

(adjustable-speed machine)

*After renovation

Tokyo Electric Power Company Renewable Power Company Kannagawa Power Plant

Tokyo Electric Power Company Renewable Power Company Kannagawa Power Plant

525MVA Generator-motor Rotor, Stator

(Fixed-speed machine)

Hokkaido Electric Power Co., Inc.

Hokkaido Electric Power Co., Inc.

Takami Power Station

105MVA Generator-motor Rotor, Stator

(Adjustable-speed machine)

Tokyo Electric Power Company Renewable Power Company

Tokyo Electric Power Company Renewable Power Company

Kanagawa Power Station

7.45MVA generator

Republic of China

Republic of China

Tachiachi Hydro Power Station Chingshan Branch Power Station

115.5MVA generator

Control and Protection Systems

Adjustable-Speed Control Panel

The adjustable-speed control panel takes in system active power, system reactive power (voltage), and water turbine rotation speed, and calculates and outputs various control commands to control them to command values (target values), and is responsible for the core control functions of the adjustable-speed pumped storage power generation system. The controller that performs high-speed calculations for adjustable-speed control is configured as a dual system with two controllers to improve operational continuity.

Hokkaido Electric Power Co., Inc.

Hokkaido Electric Power Co., Inc.

Takami Power Plant

Adjustable-speed control panel

Automatic Control Panel

The automatic control panel receives commands from the central feeder command station or control station and performs start/stop control of the generator/turbine. The power supply and CPU (central processing unit) are redundant, while the PIO (process input/output) is a single configuration. A panel with CPU is located in the switchboard room, and a remote PIO panel is installed in the power plant, with optical cables connecting these panels to reduce the number of cables.

Kyushu Electric Power Co., Inc.

Kyushu Electric Power Co., Inc.

Omarugawa Power Plant

Automatic control panel

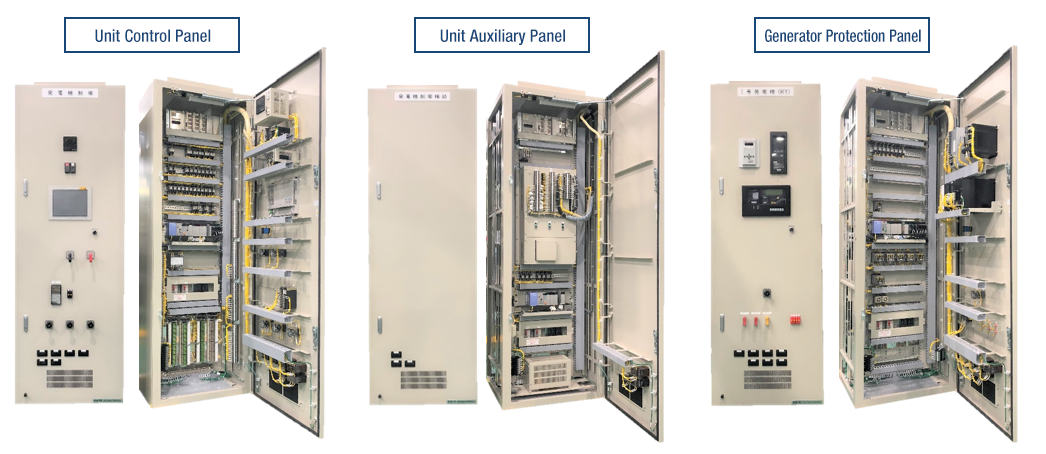

Integrated Switchboard

For general hydraulic power plants, the number of panels has been significantly reduced by integrating generator instrument panels, generator protection relay panels, automatic control panels, auxiliary panels, AVR (automatic voltage regulator) panels, and speed regulator control panels, which were previously dispersed throughout the plant, into an integrated distribution panel.

Integrated switchboard (monitoring control, AVR control, regulator control, generator protection)

Integrated switchboard (monitoring control, AVR control, regulator control, generator protection)

Features of integrated switchboards

- While using a general-purpose controller, the addition of our specially developed speed detection module enables high-speed and high-accuracy speed detection, which is difficult to achieve with a general-purpose controller.

- Digital protection relay for hydroelectric power plants meets the immunity test of the electric power standard B402. The compact structure enables waveform analysis during protective operation, which shortens the time required to determine the cause of an accident. The software logic can be configured in the protective relay to meet the customer's detailed needs.

- The instruments, indicators, and operation switches for monitoring and operation are integrated on a touch panel. The touch panel screen is our original and provides a comfortable operating environment by configuring the screen according to the purpose of monitoring/operation. The touch panel screen also displays factors when sequence congestion is detected, which has been difficult to do with conventional switchboards, and allows setting values that are frequently changed to be changed without the need for maintenance tools.

Digital Protection Relay

Digital Protection Relay

Main Menu

Main Menu

Generator monitoring operation screen

Generator monitoring operation screen

Balance of plant

HM HYDRO handles ancillary equipment such as excitation transformers, electrical components for main circuits (generator circuit breakers, Isolated phase busducts, disconnectors, etc.), power receiving and distribution equipment station service use (station service transformers, power distribution panels, etc.), and static frequency convertor for pumped storage power plants, and propose optimal packages of these ancillary equipment based on overall plant system design.

Generator Circuit Breaker

Generator Circuit Breaker

Isolated Phase Busduct

Isolated Phase Busduct

Phase-reversal Disconnecting Switch

Phase-reversal Disconnecting Switch

Exciter Transformer

Exciter Transformer

Low Voltage Power Distribution Equipment

Low Voltage Power Distribution Equipment

Static frequency convertor

Static frequency convertor