Services

HM HYDRO offers the best services to meet our customers' operations and requirements, including new plant construction and preventive maintenance of existing plants.

New Construction・Scrap-and-build

For newly constructed hydroelectric power plants, HM HYDRO can design main facilities such as turbines, generators, and control equipment tailor-made to the conditions of the installation site and the customer's requirements, and provide a complete set of mechanical and electrical facilities that make up the plant, from main circuits to substations. In the scrap-and-build (S&B) process for the renewal of existing power plant facilities, HM HYDRO investigates existing power plant facilities and examine the possibility of partial reuse, and make proposals that will benefit customers by increasing output, efficiency, operating range, maintainability, and environmental friendliness.

Scrap-and-build example

HOKUDEN ECO-ENERGY CO., LTD. Toya Power Station

Turbine Specifications

| Type |

|---|

| Vertical Francis Type |

| Before upgrading |

| 3300kW×2 units |

| After upgrading |

| 3310kW×2 units |

Generator Specifications

| Type |

|---|

| Vertical Shaft Three-Phase AC Synchronous Generator |

| Before upgrading |

| 3750kVA×2 units |

| After upgrading |

| 3600kVA×2 units |

Major Upgrades

・Removal of cooling water supply system and adoption of water-lubricated bearing, air-cooled generator

・Removal of oil pressure supply system and adoption of electric servomotor

Before upgrading

Before upgrading

After upgrading

After upgrading

Preventive maintenance・Upgrading

Overhaul

As part of the overhaul service, HM HYDRO performs non-destructive inspection of equipment welds and coil insulation diagnosis to examine equipment deterioration and suggest parts that need to be repaired or replaced.

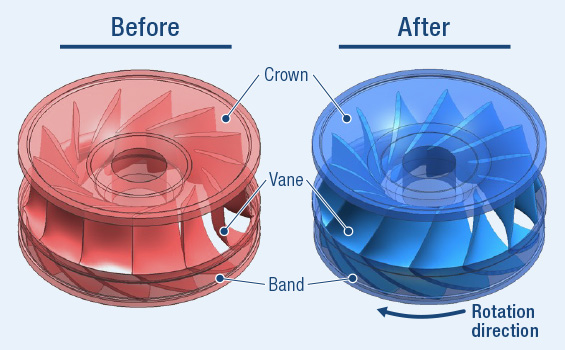

Turbine Overhaul and upgrading

Rotation direction

Rotation direction

Since cavitation erosion and sediment wear occur in the turbine runner, the condition of the runner is inspected and weld repairs are performed during overhaul.

In addition, by replacing the runner with a more efficient runner that uses the latest technology, an increase in annual power generation can be expected due to an increase in maximum power output and improved partial load efficiency, which will contribute to suppression of cavitation, vibration, and noise.

Generator Overhaul and upgrading

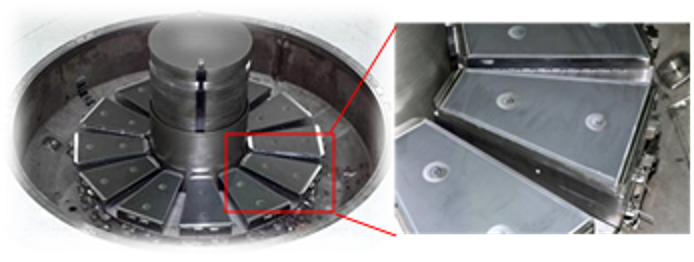

PEEK resin material

PEEK resin material

Stator coils and cores deteriorate over time. During overhaul, HM HYDRO evaluates the pre-life of the stator coils by insulation diagnosis and inspect the cores, and propose the timing of renewal, such as renewal at the next overhaul.

As an example of extending the service life of equipment by replacing parts, HM HYDRO replaces conventional white metal bearings with PEEK resin material, which has superior heat resistance, wear resistance, and mechanical properties.

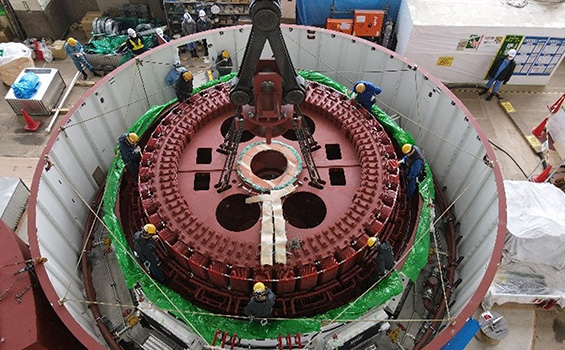

On-site work

HM HYDRO is provided to perform the construction of hydropower plant not only new one but also renewal up to large one such as pumped storage generation plant in Japan and abroad.

HM HYDRO realizes the reliable plant with our experienced skill and management to ensure the high quality and industrial safety and to meet the customer's requirement.

East Japan Railway Company

East Japan Railway Company

Senju Power Station

Stay Ring Assembly

East Japan Railway Company

East Japan Railway Company

Senju Power Station

Rotor Installation

Laos

Laos

Nam Ngiep 1 Main Power Station

Spiral Case Assembly

Laos

Laos

Nam Ngiep 1 Main Power Station

Runner Installation