Technologies

The following is an introduction to the technology of Hitachi Mitsubishi Hydro Corporation.

HM HYDRO uses state-of-the-art technology to meet the various needs of our customers, such as improved operability and environmental friendliness, and digitalization.

R&D

Turbine

CFD Analysis

HM HYDRO uses CFD analysis and verification through model tests to optimize the design of water turbines for each power plant. Here HM HYDRO introduces some of our CFD analysis technologies.

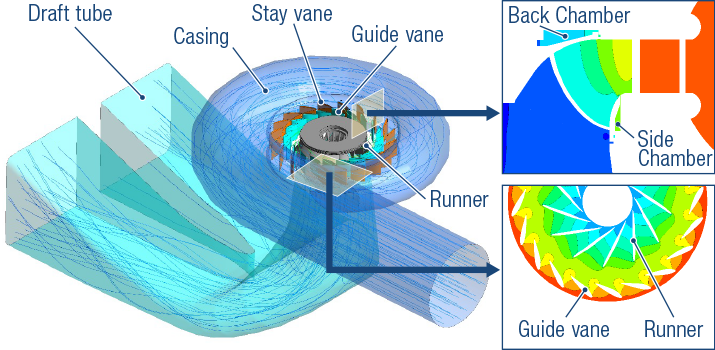

Overall analysis: Large-scale CFD analysis including all fluid components of the turbine from the casing inlet to the draft tube outlet.

Analysis object of the overall analysis

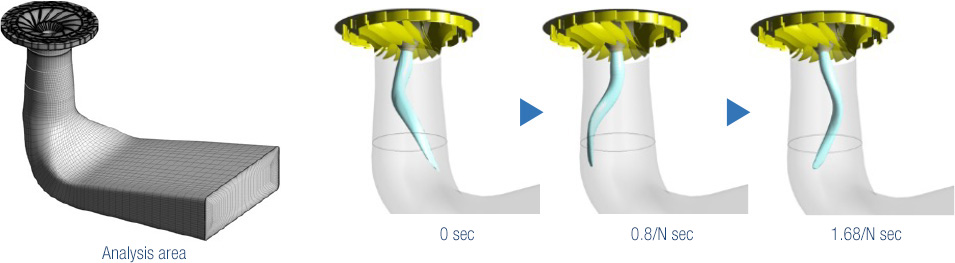

Unsteady gas-liquid two-phase flow analysis: The oscillation of helical vortices in a draft tube is simulated at the same level as in a model test.

CFD Analysis

Model test

※N:Runner rotation speed (s-1)

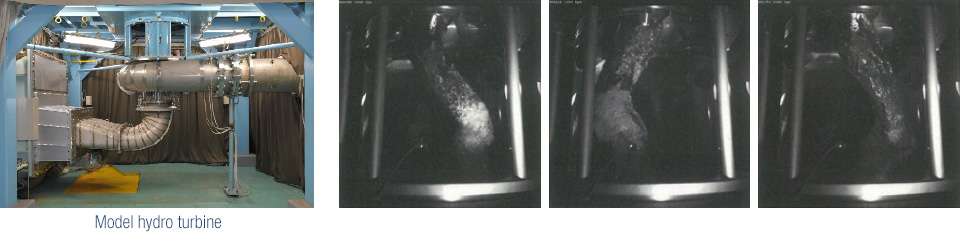

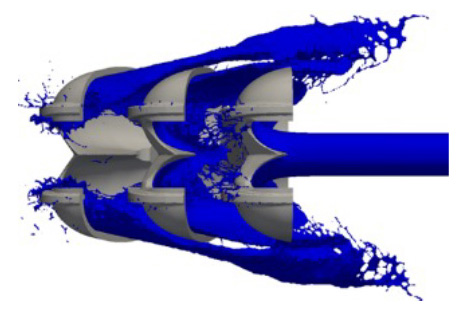

Particle method: Analysis of the outflow flow from the Pelton turbine runner bucket, which is difficult to observe in model tests.

CFD Analysis (Particle method)

CFD Analysis (Particle method)

Model test (flow observation)

Model test (flow observation)

Generator

Thermo Elastic Hydro Dynamic Analysis Program

HM HYDRO designs thrust bearings using a thrust bearing analysis program called Thermo Elastic Hydro Dynamic (TEHD). TEHD analyzes a series of the following state quantities to ensure thrust bearing performance with higher accuracy than conventional methods.

TEHD Features

Three-dimensional analysis of oil film flow and temperature (3-dimensional energy equation)

Three-dimensional analysis of oil film flow and temperature (3-dimensional energy equation)

Heat transfer from oil film to thrust pad

Heat transfer from oil film to thrust pad

Heat conduction in thrust pad (FEM (finite element method))

Heat conduction in thrust pad (FEM (finite element method))

Thermal and load deformation of thrust pad (FEM)

Thermal and load deformation of thrust pad (FEM)

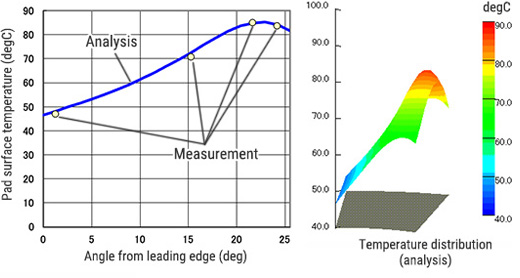

Calculated and measured thrust pad surface temperature results

Calculated and measured thrust pad surface temperature results

Calculated and measured oil film thickness results

Calculated and measured oil film thickness results

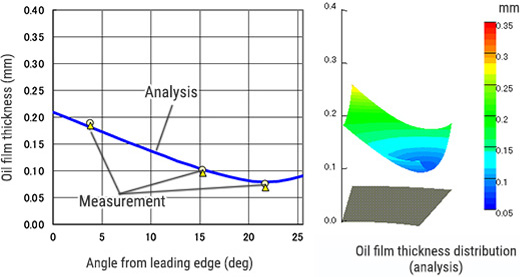

PEEK resin bearings

Among the components of hydro generators, bearings are one of the parts that require the highest reliability. On the other hand, in recent years, there has been a demand for low-loss bearings and simplified maintenance by reducing the number of auxiliaries. In response to these needs, HM HYDRO has developed and adopted PEEK (Poly-Ether-Ether-Ketone) plastic bearings, which are superior to conventional white metal bearings in terms of strength, heat resistance, and wear resistance.

Features of PEEK resin bearings

High strength under high temperature

High strength under high temperature

High heat resistance

High heat resistance

Self-lubricating and high wear resistance

Self-lubricating and high wear resistance

High impact resistance, toughness and fatigue strength

High impact resistance, toughness and fatigue strength

Excellent in chemical resistance and hydrolysis resistance, and not affected by anything other than concentrated sulfuric acid

Excellent in chemical resistance and hydrolysis resistance, and not affected by anything other than concentrated sulfuric acid

Shikoku Electric Power Co., Inc.

Shikoku Electric Power Co., Inc.

Hongawa Power Station

PEEK resin thrust bearing

Adjustable-speed Technology

From the perspective of global warming countermeasures, variable renewable energy sources such as solar power and wind power are being introduced in order to reduce CO2 emissions. However, with the increase of these variable renewable energy sources, the impact on the power system has increased, such as the generation of excess power during the day, short-time output fluctuations due to weather conditions, and rapid increases and decreases in solar power generation with sunrise and sunset, making the stabilization of the power system an issue.

The adjustable-speed pumped storage power generation system, which HM HYDRO was the first in the world to develop, is being used as a solution to this problem. For more than 30 years since the world's first demonstration test in 1987, HM HYDRO has been providing adjustable-speed pumped storage power generation systems in Japan and overseas, and our pump turbines and generator motors for adjustable-speed pumped storage power generation are applicable to high head, large capacity, and high rotational speed ranges.

Adjustable-speed pumped storage power generation systems can follow frequency fluctuations, thus ensuring frequency adjustment power, and are utilized to improve grid stability through independent and high-speed control of active and reactive power. The system also reduces CO2 emissions by improving operational economy through load frequency control (LFC) in pumped storage operation using the wide operating range of the adjustable-speed pumped storage power generation system (i.e., reducing the need for additional thermal power generation).

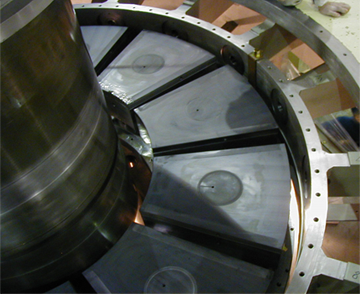

Adjustable-speed PSPP can follow load fluctuations faster than

Conventional PSPP, which can contribute to system frequency stability.

※GF:Governor Free

※GF:Governor Free

LFC:Load Frequency Control

ELD:Economic load Dispatching Control

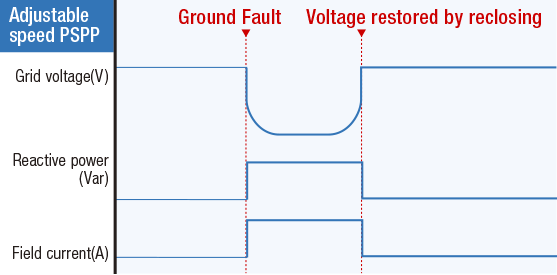

Adjustable-speed machines contribute to maintaining grid voltage because they track reactive power better than constant speed machines.

When the grid voltage drops sharply due to a ground fault accident, the adjustable-speed machine with AC excitation contributes to the recovery of the grid voltage by increasing the field current in an almost stepwise manner with the normal AVR function to compensate for the reactive power.

When the system voltage suddenly drops due to a ground fault, the field current of a synchronous machine with DC excitation is increased by the AVR function, but the long time constant makes it difficult to compensate for the reactive power in a short period of time.

*This figure is a schematic diagram to illustrate the features of adjustable-speed machine.

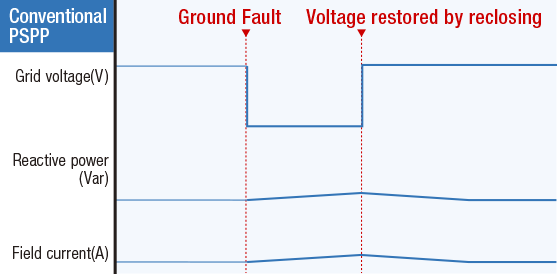

Kansai Electric Power Co., Inc.

Kansai Electric Power Co., Inc.

Okutataragi Power Station

Adjustable-speed pumped storage generator motor 350MVA

Rotor Installation

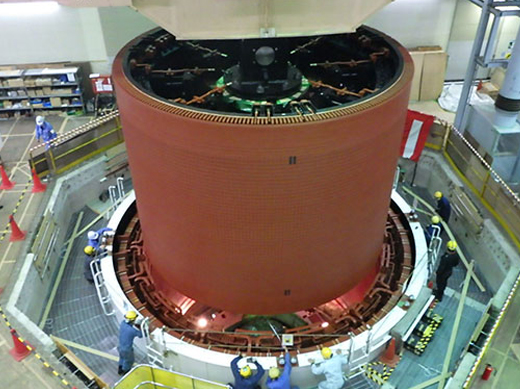

Hokkaido Electric Power Co., Inc.

Hokkaido Electric Power Co., Inc.

Takami Power Plant

adjustable-speed exciter

Environmentally Friendly Technologies

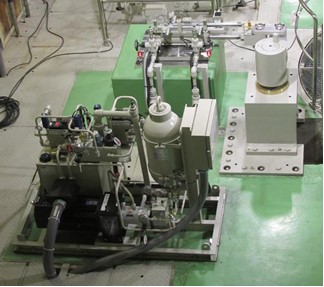

Hybrid servomotor

Hybrid servomotor is a drive system that directly pressurizes a hydraulic cylinder by means of a bidirectional pump. Application of the hybrid servomotor enables to omit the auxiliary equipment required for conventional hydraulic oil operated system, such as pressure oil supply system, pressure oil tank, air receiver, and air compressors, etc. that allows to save the space in the power plant. By applying the high pressure hybrid servomotor system, amount of oil required for generating unit control can be minimized, and that enables to reduce the environmental risk and impact.

Hybrid servomotor

Hybrid servomotor

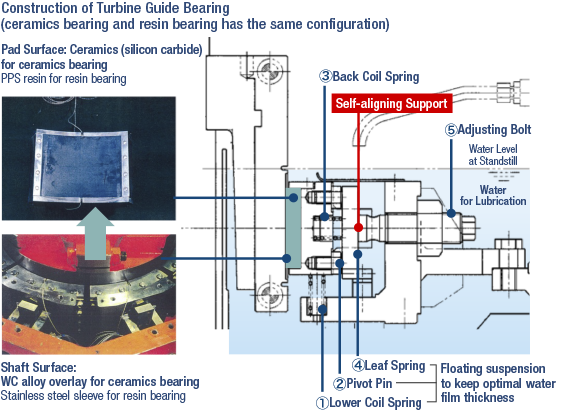

Water-lubricated ceramic bearings

Water-lubricated ceramic bearings are superior to conventional oil-lubricated bearings in the following ways

River water can be used as lubricant

River water can be used as lubricant

No need for auxiliary equipment (cooling water pump, cooler, etc.)

No need for auxiliary equipment (cooling water pump, cooler, etc.)

No possibility of oil spillage and no environmental measures are required.

No possibility of oil spillage and no environmental measures are required.

Structure of water-lubricated ceramic bearings

Structure of water-lubricated ceramic bearings

Dual electric servomotor

Although hydraulically operated servomotors have been used to open and close the guide vanes of water turbines in the past, electric servomotors are increasingly being used to prevent environmental pollution and simplify maintenance. The use of electric servomotors eliminates the need for a hydraulic oil pump, oil tank, air compressor, and associated piping, all of which are required for a hydraulically operated system, thereby reducing maintenance labor.

The availability of electrification is limited by the capacity of the electric servomotor, but HM HYDRO has developed a double-acting electric servomotor that synchronously controls two electric servomotors, making it possible to electrify even water turbines with a power range that was difficult to electrify in the past.

Kyushu Electric Power Co., Inc.

Kyushu Electric Power Co., Inc.

Tsukabaru Power Plant

Dual electric servomotor

East Japan Railway Company

East Japan Railway Company

Senju Power Plant

Dual electric servomotor

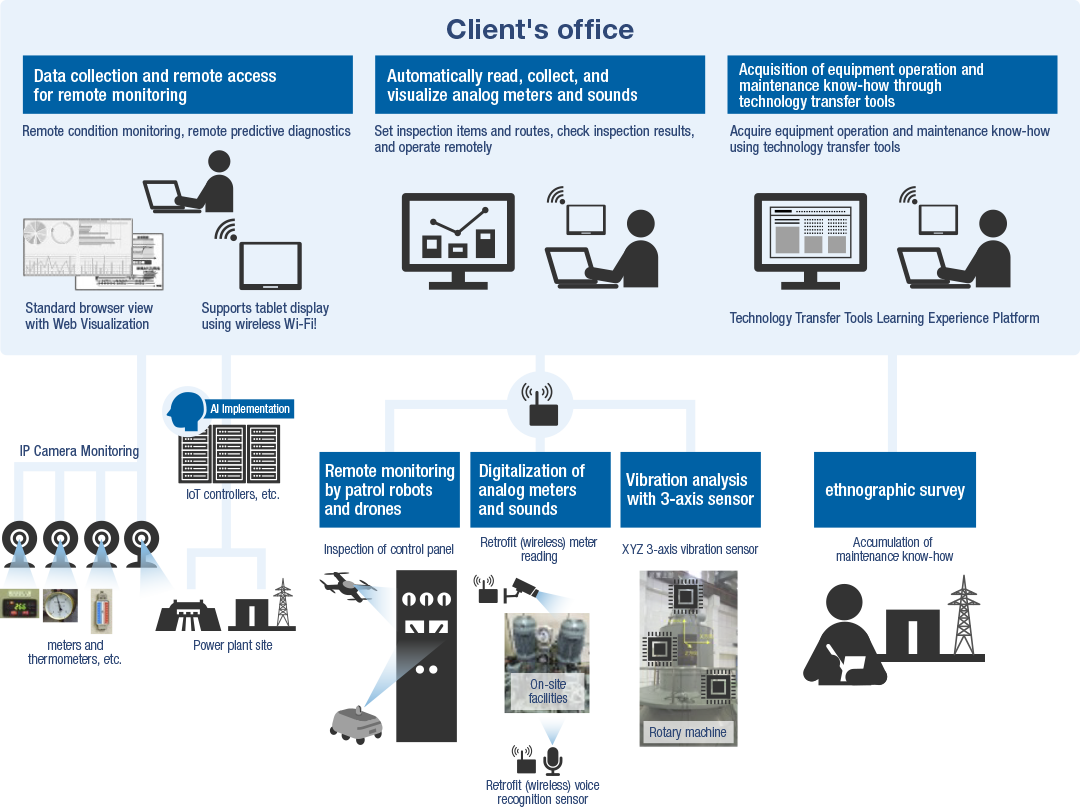

Digital Transformation

HM HYDRO supports our customers' digital transformation (DX) by upgrading security management operations at hydroelectric power plants.

Concept and Approach for Security Upgrading System

Remote supervision・Real-time monitoring

Concepts

- Supporting new lifestyles (easy to check the status of power plants anytime, anywhere)

- Contribute to the reform of work styles (support for more efficient maintenance and effective use of time)

Approach

- Visualization of power plants through web visualization, retrofit sensors (Note 1), etc.

- Easier maintenance work through the use of smart devices such as tablets (Note 2)

- Robots, drones, IP cameras, etc. to replace on-site dispatchers

Note 1: Retrofit sensors are devices that convert non-digitalized meters and gauges into numerical values through image recognition and import them into the controller. It can read analog meters with indicating needles (linear or nonlinear), liquid level gauges such as oil level gauges, 7-segment displays, counters, etc. There is also a type that compares ambient and normal sounds with a microphone and outputs the degree of abnormality.

Retrofit Sensors

Retrofit Sensors

Note 2: Real-time operating data of the generator is displayed on a mobile terminal by accessing the controller in the power plant via a wireless network such as a VPN (Virtual Private Network). This enables monitoring of status, measurements, and failures from remote locations. The system is also planned to be used for patrol and inspection work, and to be linked with tools for handing down technology.

Tablet terminal for remote monitoring

Tablet terminal for remote monitoring

Objectivity and sophistication of judgment

Concepts

- Ensure facility safety through early detection of abnormalities unnoticed by humans, reduce the frequency and scale of repairs, and reduce the risk of unplanned outages

- Reduction of time to determine the cause of a problem and recovery time when a problem occurs

Approach

- Predictive maintenance by coupling collected data with AI

Knowledge aggregation of field operations

Concept

- Efficient accumulation and sharing of knowledge and know-how

Approach

- Visualization and accumulation of knowledge and know-how of skilled workers through the use of technology transfer tools